Skip to content

-

Core business is rotary cutting tools. Specializing in end mills, drills, step drills, reamers and step tools. Range: 3mm to 50mm diameter.

-

Capable of grinding most high performance drill points available in the industry.

-

Re-sharpen just about any rotary cutting tool, milling cutter, tap, etc.

-

Alter standards purchased from a variety of cutting tool suppliers or re-work a tool supplied by the customer in carbide, carbide tipped or high speed steel.

-

Creative programs customized to the customer’s needs to help reduce down time and avoid spikes in tooling costs on long term jobs. This is accomplished by conducting the initial life cycle of tools we manufacture and re-sharpen, calculate the life expectancy and arrive at a set cost for the tool. This will avoid budget conflicts and at the same time, ensure the appropriate number of tools required to maintain a proper float.

-

Alterations: Supplied tools are altered in a week or less.

-

Regrinds: Typical turnaround time for regrind is one week or less.

-

Manufacturing: Tools can be produced in two weeks or less.

-

All the major coating companies in our area pick up and deliver daily to our facility allowing for quick turnaround on coated tools.

-

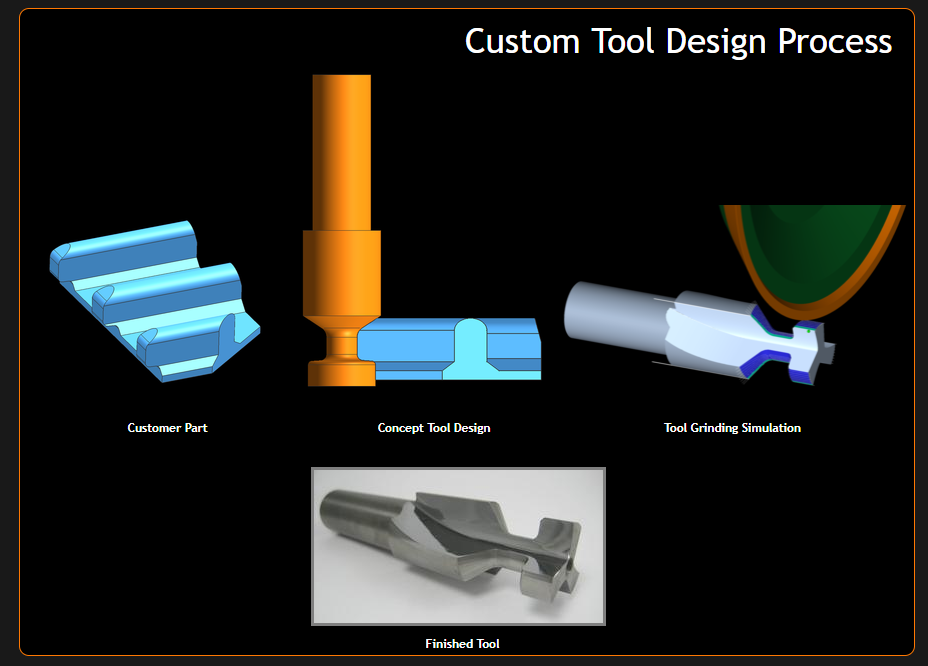

CAD drawings available on special tools when ordered. Our design or the customers - from concept sketch or part print to a formal drawing for customer approval.

Scroll To Top